Share this

Battery Internal Ohmic Measurements – Part 3 (Importance of Context)

by PowerShield on Mar 11, 2020 5:28:47 PM

Introduction

In part 1 we introduced ohmic measurement and some of its challenges. In part 2 the four-wire connection was explained as was the influence the connection type can have on the reading.

This article will look wider and consider what the battery may be connected to. We explain that an online battery ohmic reading can be influenced by parallel paths to the battery string – for example the charger, load, or other batteries. This influence is typically only significant in strings with a small number of batteries i.e. two or four batteries in a string.

Explanation

To measure battery impedance, a known test signal is applied to the battery and its voltage response measured.

This influence is usually only significant in small battery strings, for example two batteries in a string. The level of influence also depends on the cable resistance, battery charger, other parallel battery strings, load, and anything else in the circuit.

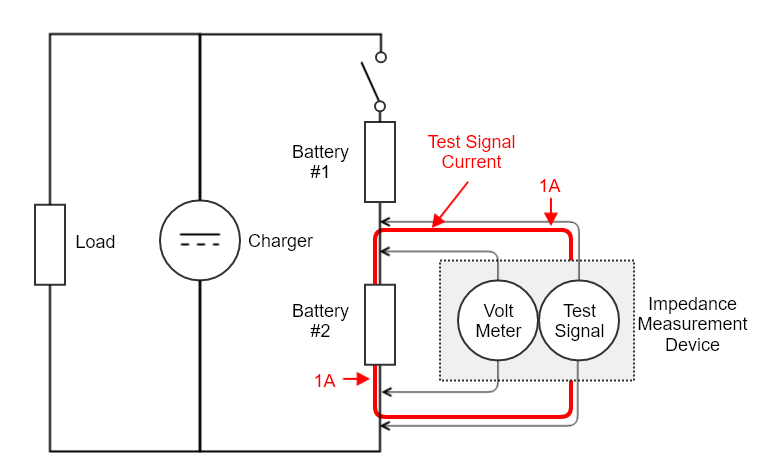

To understand why the battery impedance reading can be influenced, one way is to take a look at the path of the test signal. In figure 1, battery #2 is being measured and the test signal current is shown in red. The string breaker open, the total test signal current is flowing through battery #2.

Figure 1

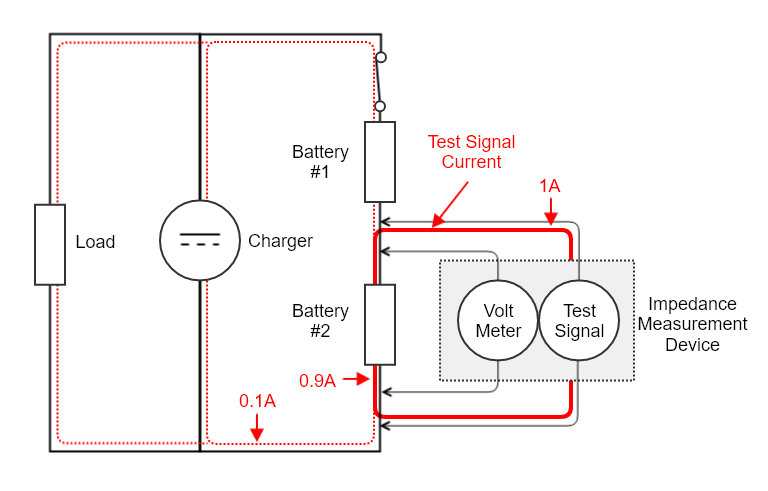

When the string breaker is closed the current path of the test signal has changed and shown in Figure 2.

Figure 2

From Figure 2 you can see that the test signal current through Battery #2 is reduced because some of the test signal is flowing through other parts of the circuit.

For the impedance measurement device to provide a reading the formula is: \(|{Z}|={V\over I}\)

| Z | is impedance, V is voltage and I is current. The Voltmeter measures V and the Test signal is I.

For example, let’s say that Battery #2 is 5mΩ and that the impedance of the parallel path causes the test signal current to have a 90/10 split. Battery #2 has 0.9A test signal going through it.

In Figure 1 when the test signal of 1A is applied, a battery a voltage is measured of 5mV.

Battery #2 impedance \({5mV\over 1A} = 5mΩ\)

In Figure 2 when the test signal of 1A is applied 0.9A flows through the battery so a voltage is measured of 4.5mV.

Battery #2 impedance \({4.5mV\over 1A} = 4.5mΩ\)

The impedance of Battery #2 has not changed, but in closing the breaker the reading has changed because the circuit has changed and the test signal through Battery #2 is less.

Experiment

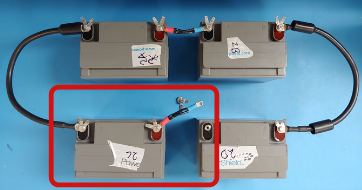

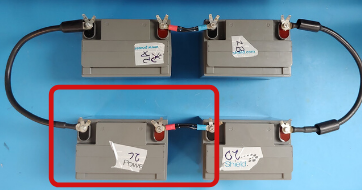

To demonstrate the effect with some actual measurements, two measurements are taken on a battery in the following configuration where the battery is out of the circuit and in circuit. This configuration is where the effect is most significant.

Equipment:

- 4 x VRLA batteries 32Ah

- Interlink cables

- Hioki BT3554-01 battery tester

| Configuration | Result |

|

Battery out of the circuit |

Battery = 6.06mΩ |

|

Battery in circuit |

Battery = 4.68mΩ |

The change in reading is (6.06 - 4.68)/6.06 x 100 = 23%

Another example is a configuration with two UPS battery strings of 32 x 12V batteries per string.

A battery out of circuit = 6.53mΩ, a battery in circuit/online = 6.36mΩ

The change in reading is (6.53 – 6.36)/6.53 x 100 = 2.6%

As you can see the amount of change in the impedance measured largely depends on the number of batteries in a string.

Conclusion

The battery impedance reading is influenced when a measurement is taken when the battery is in service/online, however the level of influence mainly depends on the number of batteries in the string. In the experiment there was a 2.6% change for the string of 32 batteries and a 23% change for a string of 2 batteries.

As we highlighted in this series on Ohmic Measurements, good impedance trending relies on a consistent measurement context. A change from offline/disconnected measurement to online measurement, or a change in installation arrangement, may affect individual measurements and create data that is out of context. Consideration also needs to be taken with regards to the baseline and the percentage of change for the alarm threshold.

When trending battery impedance measurements for installations with a small number of batteries per string, any changes to the installation [such as addition of a new parallel string] must be recorded and that information made available to the person interpreting the results. A change in battery impedance may be due to an installation change and not the battery itself.

For further insights into the topic of impedance measurement, explore the other articles in the series:

Battery Internal Ohmic Measurements Explained – Part 1 (Impedance)

Battery Internal Ohmic Measurements Explained – Part 2 (Kelvin Connection)

Share this

You May Also Like

These Related Stories

Thermal Runaway and Thermal Walkaway

Battery Internal Ohmic Measurements Explained - Part 1 (Impedance)

All things big and small

- September 2024 (1)

- December 2021 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- October 2019 (2)

- July 2019 (1)

- May 2019 (2)

- April 2019 (1)

- March 2019 (2)

- January 2019 (1)

- December 2018 (1)

- November 2018 (1)

- August 2018 (3)

- July 2018 (1)

- June 2018 (2)

- May 2018 (2)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- November 2017 (1)

- October 2017 (1)

- August 2017 (3)

- June 2017 (1)

- March 2017 (1)

- November 2016 (1)

- October 2016 (1)

- September 2016 (2)