Share this

All things big and small

by PowerShield on Oct 27, 2017 7:58:24 AM

This is the first in a series of units that will educate the reader on the part played by a battery in an uninterruptible power system (UPS).

The three main subsystems of a UPS are:

1) Rectifier/charger - Converts alternating current (ac) into direct current (dc) used to maintain the battery at a constant state of charge

2) Battery system - Stores energy; includes multiple cells, mounting equipment, protective devices, and monitoring

3) Inverter - Converts dc back into ac for consumption by the critical load(s)

Other elements include such things as static bypass, maintenance bypass, protective devices, controls, and distribution equipment.

Of the three main subsystems, the battery is what makes the system “uninterruptible”. Depending upon the system design, the battery can constitute as much as 50% of the cost of the UPS. Without a reliable battery, the operation of the entire data center can be put at risk. Power interruptions are rare and unpredictable, but when they occur they can disrupt the entire business or operation. Costs of downtime can range from hundreds to millions of dollars, depending upon the mission of the data center.

It is the nature of a battery system to be composed of many connected parts such as cells and interconnecting cables. Each cell is likewise made of components such as plates, containers, separators, and electrolyte. Failure of one or more of any component(s) can impact the performance of this critical subsystem. Usually there is no visible indication that a failure is imminent. That is why particular attention is paid to monitoring and maintenance.

BATTERY TYPES

Batteries are available in a sometimes bewildering range of technologies, including lead-acid, nickel-cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these, lead-acid continues to be the battery of choice in about 95% of all UPS applications. The reasons: price, availability, and proven performance.

Within lead-acid, there are still more variations. It is important to focus on two main form factors:

• Valve-Regulated Lead-Acid (VRLA) is the most popular because of its convenience of use.

• Vented Lead-acid (VLA), also known as “flooded lead-acid,” is still used in some UPS applications, especially those in the megawatt range.

Details on the trade-offs of these batteries will discussed in the next unit.

MONITORING VERSUS MANAGING

The old adage goes, ‘You can’t manage what you can’t measure.’ The two functions, while intertwined, are separate.

Monitoring a battery requires the ability to know the “state of health” of a battery at any given moment. We can measure things such as temperature, voltage, current, and resistance. As batteries grow older they lose the ability to perform. This ability to perform is usually expressed as “back-up time.” A battery that originally was able to support load “X’ for fifteen minutes might deteriorate to only supporting the same load for twelve minutes. Generally speaking, when a lead-acid battery is able to deliver only 80% of its original capacity, it is time to replace the battery. Battery replacement can be very expensive in both labor and material, so it is desirable to postpone such an event for as long as possible.

Managing a battery helps prolong the life the battery for as long as possible. By physically inspecting or remotely monitoring a battery, we can make predictions about when a failure is likely to occur and take proactive measures.

The units that follow will each address topics in greater detail. While the goal of this series is not to make the reader into a certified technician, the reader will be able to talk intelligently about UPS batteries and understand how to maximize the investment in a battery system. Future topics will include:

• Battery configurations in data centers

• Common battery terminology

• Charging regimes

• Failure modes in lead-acid batteries

• Battery environmental considerations

• Battery maintenance

• Battery installation and commissioning

• Monitoring battery state of health

• Replacement intervals

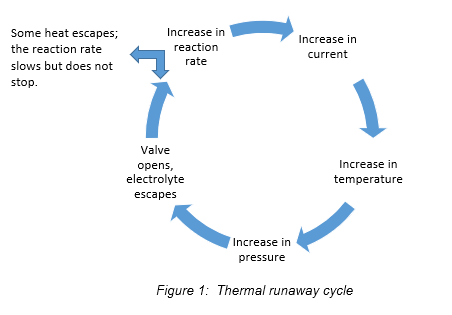

• Thermal runaway vs. thermal walkaway

• Applicable codes and standards

• Case studies

If you want to sign up to receive the following units as they are released, sign up to our newsletter here.

Share this

You May Also Like

These Related Stories

Thermal Runaway and Thermal Walkaway

Battery charging regimes

Battery configurations in data centers

- September 2024 (1)

- December 2021 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- October 2019 (2)

- July 2019 (1)

- May 2019 (2)

- April 2019 (1)

- March 2019 (2)

- January 2019 (1)

- December 2018 (1)

- November 2018 (1)

- August 2018 (3)

- July 2018 (1)

- June 2018 (2)

- May 2018 (2)

- March 2018 (2)

- February 2018 (2)

- January 2018 (1)

- November 2017 (1)

- October 2017 (1)

- August 2017 (3)

- June 2017 (1)

- March 2017 (1)

- November 2016 (1)

- October 2016 (1)

- September 2016 (2)